Smart microfluidics hub

Our new smart microfluidics hub, is designed to simplify your experiment set up. The "galet" design underlines the French Riviera origine of our device and the zen feeling we want you to experience on your microfluidics journey.

Main features

-

4 pressure/ vacuum flow controlers

-

Silent, vibration free

-

WIFI/ USB/ Ethernet connexion

-

4 to more add-on modules slots (USB-C ports)

-

Programmable interface

Driving fluids modules

Thanks to our experience in the development of full automatized and user-friendly instruments, we propose various available functionnalities easily recognized and linked with the hub.

-

5 channels microfluidic valves controller

-

Flow-sensor units (Flow control)

Accessories & starting kits

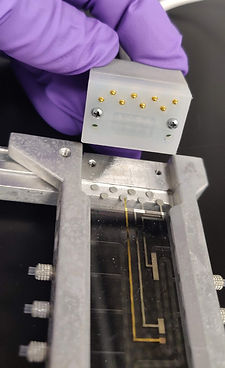

Glass microfluidics universal holder

This ergonomic metallic holder with lateral fluids handling enables easy and hassle-free interface between the chip and your setup. Just choose the fitting you prefer (upchurch or luer) and start experimenting: Forget about the leaks!

-

Easy sliding rack fixed by two M2x10 screws

-

Suitable for standard microscope stages

-

Up to 16 fluidics connections (8 left/8 right)

-

Connect to 30 mm Teflon 1520M

-

Until 8 electrical banana jack plug-in for LoC

Full automatized and portable instruments

Looking to bring your innovation to life?

KLEARIA supports you, thanks to its experience and its experts in instrumentation & industrialization, in the creation and automation of your instruments according to your needs:

- Mechanical concept

- Electronic design

- Software design

- Creation of an automated, portable and / or online system

More informations:

mail : labinglass@klearia.com

Klearia S.A.S

61, Avenue Simone Veil

CEEI Nice Côte d'Azur - Immeuble Premium

06200 NICE

FRANCE